Material

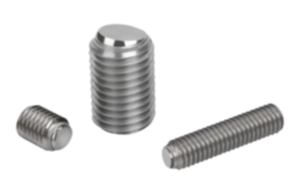

Body carbon steel.

Ball:

Form C, F tool steel.

Form K POM.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane face.

Ball:

Form C, F tool steel.

Form K POM.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane face.

Version

Body tempered, black oxidised.

Ball:

Form C, F hardened, black oxidised.

Form K POM ball, white.

Form O surface comparable to 100 grade abrasive grit.

Form P polyurethane, hardness 60 Shore.

Ball:

Form C, F hardened, black oxidised.

Form K POM ball, white.

Form O surface comparable to 100 grade abrasive grit.

Form P polyurethane, hardness 60 Shore.

Show more

Show less

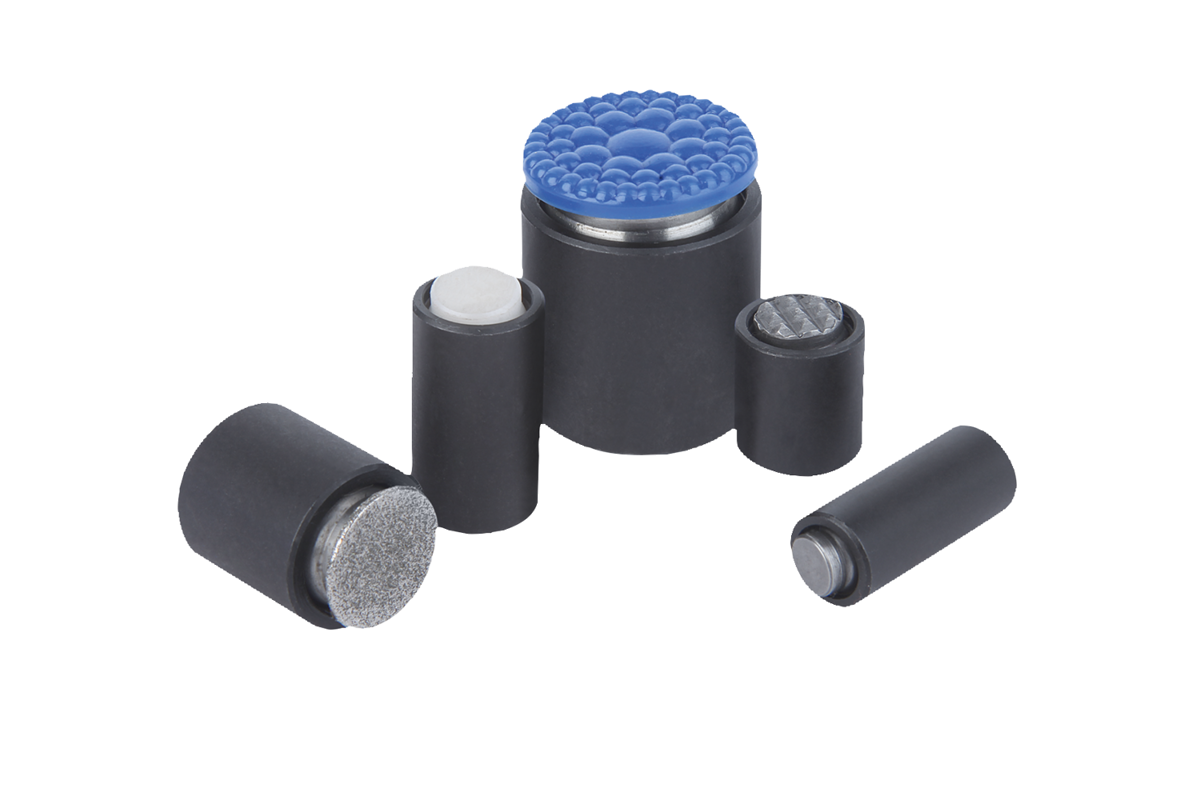

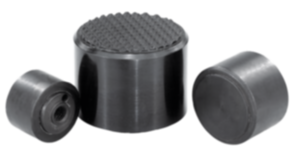

Self-aligning pads with O-ring, Form C, flattened steel ball smooth

from

955,24 CZK

plus sales tax

plus shipping costs

Self-aligning pads with O-ring, Form F, flattened ball with diamond grip

from

1 025,02 CZK

plus sales tax

plus shipping costs

Self-aligning pads with O-ring, Form K, flattened POM ball smooth

from

919,78 CZK

plus sales tax

plus shipping costs

Self-aligning pads with O-ring, Form O, stainless steel ball with diamond impregnated face

from

1 066,49 CZK

plus sales tax

plus shipping costs

Self-aligning pads with O-ring, Form P, stainless steel insert with polythene face

from

1 036,75 CZK

plus sales tax

plus shipping costs

Description

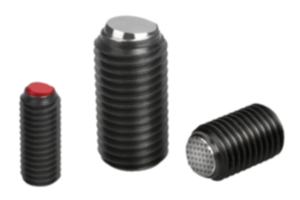

Material

Body carbon steel.

Ball:

Form C, F tool steel.

Form K POM.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane face.

Ball:

Form C, F tool steel.

Form K POM.

Form O stainless steel diamond impregnated.

Form P stainless steel with polyurethane face.

Version

Body tempered, black oxidised.

Ball:

Form C, F hardened, black oxidised.

Form K POM ball, white.

Form O surface comparable to 100 grade abrasive grit.

Form P polyurethane, hardness 60 Shore.

Ball:

Form C, F hardened, black oxidised.

Form K POM ball, white.

Form O surface comparable to 100 grade abrasive grit.

Form P polyurethane, hardness 60 Shore.

Note

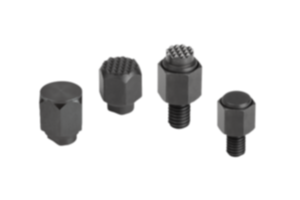

Self-aligning pads are used to support and clamp unmachined and machined workpieces.

They also serve as stops, supports and thrust pads in fixtures and toolmaking.

Ball secured against rotation.

Form O: The abrasive diamond surface is fused firmly to the ball. It is ideally suited to supporting smooth or slippery applications with a minimum of clamping pressure. This allows the diamond particles to get a firm grip on a very small area with minimum damage to the surface. The diamond surface offers excellent wear resistance.

Form P: The polyurethane surface is permanently vulcanised on the ball. It is abrasion-resistant and does not discolour. Offers optimum protection against damage to delicate surfaces. The pearl-like surface gives a firm grip and allows air to escape so as to prevent any suction effect between the contact surface and the self-aligning pads.

They also serve as stops, supports and thrust pads in fixtures and toolmaking.

Ball secured against rotation.

Form O: The abrasive diamond surface is fused firmly to the ball. It is ideally suited to supporting smooth or slippery applications with a minimum of clamping pressure. This allows the diamond particles to get a firm grip on a very small area with minimum damage to the surface. The diamond surface offers excellent wear resistance.

Form P: The polyurethane surface is permanently vulcanised on the ball. It is abrasion-resistant and does not discolour. Offers optimum protection against damage to delicate surfaces. The pearl-like surface gives a firm grip and allows air to escape so as to prevent any suction effect between the contact surface and the self-aligning pads.

Advantages

The built-in O-ring holds the ball in place and keeps dirt and foreign particles out ensuring smooth and even movement.