Material

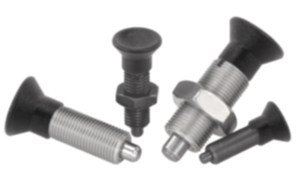

Steel version:

indexing pin hardened: grade 5.8

Stainless steel version:

indexing pin hardened: threaded sleeve 1.4305, indexing pin 1.4305.

Mushroom knob black grey thermoplastic.

Version

Steel version:

indexing pin hardened, ground and black oxidised.

Stainless steel version:

indexing pin hardened, ground and bright.

indexing pin hardened, ground and black oxidised.

Stainless steel version:

indexing pin hardened, ground and bright.

Show more

Show less

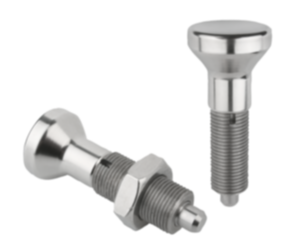

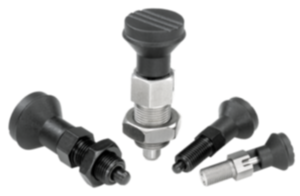

Premium - Indexing plungers, steel or stainless steel with plastic mushroom grip and cylindrical indexing pin

from

434,07 CZK

plus sales tax

plus shipping costs

Premium - Indexing plungers, steel or stainless steel with plastic mushroom grip, cylindrical indexing pin and locknut

from

437,89 CZK

plus sales tax

plus shipping costs

Premium - Indexing plungers, steel or stainless steel with plastic mushroom grip, cylindrical indexing pin and locking slot

from

477,75 CZK

plus sales tax

plus shipping costs

Premium - Indexing plungers, steel or stainless steel with plastic mushroom grip, cylindrical indexing pin, locking slot and locknut

from

481,03 CZK

plus sales tax

plus shipping costs

Description

Material

Steel version:

indexing pin hardened: grade 5.8

Stainless steel version:

indexing pin hardened: threaded sleeve 1.4305, indexing pin 1.4305.

Mushroom knob black grey thermoplastic.

Version

Steel version:

indexing pin hardened, ground and black oxidised.

Stainless steel version:

indexing pin hardened, ground and bright.

indexing pin hardened, ground and black oxidised.

Stainless steel version:

indexing pin hardened, ground and bright.

Note

Premium indexing plungers are characterized by more stringent manufacturing requirements for the indexing plungers and threaded sleeve. In addition, a centring locator that can be used to increase the positioning accuracy is provided on the threaded sleeve. These indexing plungers are used when it is necessary to prevent shifting of the locked position by transverse forces and greater positioning accuracy is required. A new locking position can only be set after the pin has been manually disengaged. When high lateral forces are to be expected, the centring locator should be used.

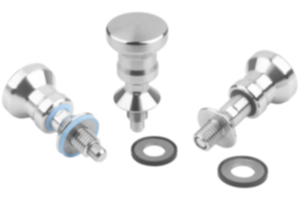

Assembly

When using the threaded sleeve centring, it is recommended the receiving reamed hole be machined before tapping.

On request

Special versions and spacer rings.

Drawing reference

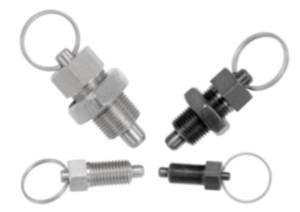

Form A: non-lockout type, without locknut

Form B: non-lockout type, with locknut

Form C: lockout type, without locknut

Form D: lockout type, with locknut

Form B: non-lockout type, with locknut

Form C: lockout type, without locknut

Form D: lockout type, with locknut

Accessory

Matching cylindrical bush K0736.

Locknut K0700….

Locknut K0700….