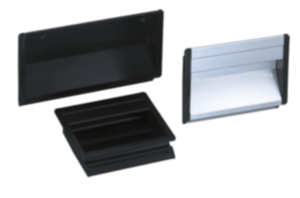

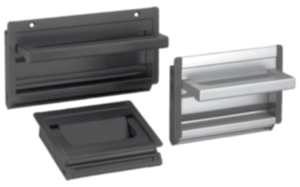

Pull handles / Pull handles, arch

Pull handles by KIPP

Pull handles are supporting elements that feature a U-shaped structure. The handles are also known as arch handles. They are used as carrying handles, grips, door and bonnet handles.

Such handles are used in mechanical engineering, plant construction, toolmaking, sports equipment construction, the furniture industry and in rehabilitation and medical technology. Here supporting elements are used for opening, closing or carrying.

Basic function of pull handles is to allow for gripping, pulling, pushing or carrying of objects. Due to their shape, they offer steady and ergonomic handling. The handles make it easier to open and close covers or panelling. Moving drawers or carrying loads is also easier.

The shape of pull handles allows for easy and ergonomic handling. The handle is designed so that the fingers may grip and pull comfortably.

Pull handles are sturdy and made of different materials. These include aluminium, machining steel, thermoset, stainless steel, grey cast iron, polyamide, polyphthalamide GF50, polypropylene, steel and thermoplastic. These handles are also available in different sizes and designs to meet various practical requirements.

Being so versatile makes pull handles an indispensable component in many industries and applications.

Types of pull handles

With a wide variety of pull handles, KIPP is one of the leading German suppliers. The product range includes different shapes of pull and arch handles. This diversity allows for a wide range of applications in different industries and areas of use.

To help you find the right handle, you may filter according to the following criteria:

- Shape

Choose between oval, round and angular pull handles. This allows you to find the right look and ergonomics for your application. Oval pull handles are characterised by a soft, ergonomic shape. They fit the hand particularly well and enable even distribution of force. They are ideal for applications where convenience and comfortable gripping is paramount. Particularly noteworthy is the oval arch with removable handle. On YouTube you can watch a video on the use of removable pull handles.

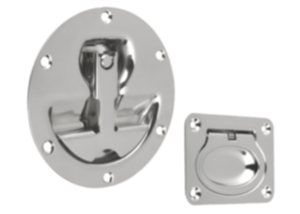

Round pull handles offer a balanced look and feel. Due to their even shape, they can be gripped equally well in any direction. This makes them a versatile choice for applications where flexibility and secure grip are required.

Angular pull handles on the other hand, impress with a clear, functional form, often favoured in industrial and technical areas. Their straight lines offer particularly firm and controlled grip. This makes the handles ideal for demanding and precise work.

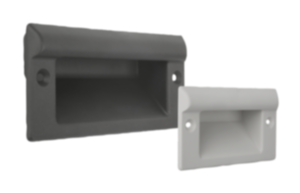

- Mounting options

Different mounting options of pull handles - front, rear or on both sides - offer varying advantages depending on the application.

Front-mounted pull handles are the most common solution. They offer easy and direct access and can be dismounted quickly.

Rear-mounted pull handles are often found in applications where protected mounting is required. This version ensures that fastening elements remain invisible and do affect the design of the object.

For maximum flexibility handles can be mounted on both sides. This solution is primarily chosen for heavy or large applications.

- Material of the base body

Our pull handles are available in different materials. Our material overview provides all the details in regard to individual materials.

In addition to products already mentioned, we also offer premium-quality pull handles for particularly demanding applications. All handles have good haptics to ensure comfortable handling.

Customer favourites:

- Plastic pull handles

- Aluminium pull handles, oval

- Aluminium finger grips, round

- Steel or stainless steel pull handles, round, foldable

ESD pull handles

ESD handles are ideal for work areas in which static charges caused by electricity have to be avoided. The handles are also known antistatic pull handles. Due to an antistatic surface coating, these handles prevent electrical discharges and ensure safety in sensitive environments.

MEDIgrip pull handles

These antibacterial pull handles feature a micro-silver coated surface. This reduces bacterial colonisation on the handle.

MEDIgrip is a product line by KIPP specially developed for use in medical environments. The antibacterial pull handles fulfil the highest standards of hygiene, precision and reliability. However, the handles can also be used in other hygienic environments such as the food industry.

Heat resistant pull handles

For applications in thermally stressed environments, we offer high-temperature resistant pull handles. The handles are made of high-quality, glass fibre-reinforced thermoplastic PPA. The material is heat-resistant and durable.

Heat-resistant handles are available in a plain black finish. They are perfect for applications that require heavy loads and high temperatures.

Mounting holes are designed so that handles can be mounted either from the operating side or the rear using a socket cap screw or a hexagonal nut.

The continuous use temperature range, according to IEC 216, lies between a maximum of 150 °C to 160 °C. When briefly used, the handle is able to withstand a maximum usage temperature of up to 250 °C.

Advantages of pull handles

Pull handles offer numerous advantages making them a perfect solution for many applications. Whether in the furniture industry, mechanical engineering or transport - pull handles do not only offer a high level of comfort. They are also durable and enable sturdy handling. Now let's explain the main advantages of the profile in more detail.

- Ergonomic handling: The shape of pull handles provides a comfortable grip, which facilitates operation and reduces hand strain.

- Sturdiness: Pull handles are sturdy and hard-wearing, which ensures their durability and reliability. Made of high-quality materials, these handles are suitable for all kinds of applications. Some are heat-resistant and resistant to chemical influences, others are weatherproof and hygienic.

- Versatility: Pull handles are perfect for a variety of applications where frequent opening and closing is needed. Their versatility makes them the universal solution for various needs. They are used in mechanical engineering, the transport sector and construction industry.

- Easy fitting: Pull handles are easily mounted to different surfaces, making them user-friendly. The handles can be mounted from the front, rear or both sides.

- Ergonomic design: The handles are designed to fit the hand comfortably, which increases user-friendliness. They fit the hand perfectly and offer a secure, firm grip due to their ergonomic shape. The ergonomic design is particularly advantageous for intensive use.

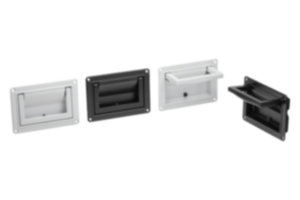

- Wide range of colour options: Handles are also available in different colours, which can be useful when marking different areas or machines. They can be used, for example, to colour-code workstations or identify functions.

KIPP as a specialist for supporting elements

KIPP is one of the leading global manufacturer of operating parts, clamping technology and standard elements. Since its foundation, the company has developed into an important partner for industry, mechanical engineering and the craft sector.

We are known for innovative solutions and high quality products. Our product range includes a wide range of standard components such as grips, levers, hinges and fastening elements. All our products are in use in many industries.

Besides standard solutions, we also offer custom made products tailored to your specific needs. We pride ourselves on in-house development, state-of-the-art production technologies and strict quality controls.

The combination of quality, innovation, versatility and customer focus makes our pull handles the perfect choice in a wide range of applications.

Should you have any further questions or suggestions, please contact us. Let us be your first choice when it comes to pull handles! Contact us!