Shaft collar / Clamping hubs

Shaft collars, locking rings and clamp hubs by KIPP

To ensure the function and performance of assemblies, precise fastening methods play a crucial part in mechanical design and machine construction. Clamp hubs as well as shaft collars and locking rings are indispensable operating partsthat allow for reliable fixation and precise positioningof components on shafts and axles.

They are important across a wide range of applications, from industrial machines to vehicle drives. These three operating parts - clamping ring, adjusting ring and clamping hub - play a central role in the industry! Here the requirements as to performance, reliability and precision are particularly high. Nevertheless, operating parts are indispensable in factories and production plants for the correct alignment and securing of machine components. The fastening elements not only make a significant contribution to stability and efficiency of mechanical systems, but also guarantee stable connection. Quick and easy installation and disassembly of the parts increase productivity and flexibility in day-to-day work.

What are shaft collars, locking rings and clamp hubs?

The difference between the three operating parts

Types of shaft collars, locking rings and clamp hubs

Selection criteria and installation of operating parts

KIPP as a reliable partner for shaft collars, locking rings and clamp hubs

What are shaft collars, locking rings and clamp hubs?

Shaft collars are mechanical components use to precisely set the axial position of shafts, bearings and other rotating parts. They are frequently used in machine construction, the automotive industry and other technical applications. Shaft collars typically consist of a ring with one or more slots and a screw. The screw is used to tighten or loosen the ring. By tightening the screw the shaft collar is fastened, accurately attaining axial positioning of the component. Shaft collars offer a simple and reliable approach of setting the position oof rotating components and can easily be adjusted or removed if required. The KIPP range includes shaft collars in various sizes, materials and styles to meet requirements of different applications.

By using a clamping ring components can be fixed in place. The locking ring allows for precise axial positioning at the same time. Operating parts are often used in mechanical engineering, the automotive industry and other technical applications. Locking rings typically consist of a ring-shaped body with one or more clamping elements that create a non-positive connection between ring and shaft or axle when tightened. This is usually done using screws or other fastening elements. Clamping elements in the locking ring apply equal pressure to the shaft providing secure gip and precise fixation of the component.

A clamp hub secures components such as wheels, gear wheels or other rotating elements on a shaft or axle. A clamp hub is often used in areas such as machine and vehicle construction. It consists of a cylindrical part with a central bore that fits onto the shaft or axle, as well as fastening elements that serve to mount the hub securely.

The difference between the three operating parts

Clamp hubs, just like shaft collars and locking rings, are mechanical fastening elements. Operating parts are used to fasten component on a shaft or axle. Despite having very similar functions, there are some differences between them.

The main difference here is the way in which they fasten and position components. Shaft collars are mainly used to precisely determine the axial position of components. So does the locking ring but compared to a shaft collar it often offers stronger fixation. Clamp hubs, on the other hand, are used to fasten rotating components.

While a shaft collar is a ring with one or more screws the component to be clamped is clamped in the locking ring. The inner diameter of the shaft collar limits the size of the component, which fastened by the screws. With locking rings, the ring-shaped body secures the component by tightening the body with the screws.

Clamp hubs consist of a cylindrical part with a central bore. These bores fit the shaft. To fasten the hub securely, they have additional fastening elements.

Types of shaft collars, locking rings and clamp hubs

The category "operating elements includes 12 different products. These are differentiated by the inside or outside diameter.

Locking rings

The KIPP range includes eight different locking rings.

- Locking rings slitted inside as well as wide locking rings slitted inside . Locking rings slitted inside provide forequal distribution of clamping forces. This results in a precise fit and high clamping forces without damaging the mating component. The shaft tolerance should be h11 or better. The wide locking ring has two grub screws.

- Locking rings slitted outsideare also available as wide locking rings slitted outside. The slit on the outside of the locking ring, compared to the one with the slit on the inside, allows for clamping forces of up to 15 % higher to be achieved. The bore remains cylindrical, in doing so precisely enclosing the shaft. The wide style has two grub screws.

- Slitted shaft collars with clamping lever Have a dimensionally accurate fit and very high clamping forces. The clamping lever allows for clamping and loosening of the locking ring with only one handle.

- Two-piece locking rings differ from conventional locking rings in that they are divided into two or more sections. The division allows for easier installation and disassemblywithout having to remove other components from the shaft. Locking rings made of A4 stainless steel additionally have a small centre point mark on the OD. The mark makes it easier to align and install the ring.

- Wide two-piece locking rings have to grub screws with hexagon socket. This type of locking ring can be used at temperatures of -40 to +175 °C. Thanks to their two-piece design wide two-piece locking rings permit simple and quick installation. Two-piece locking rings with an inner slit surround the shaft with equal distribution of clamping forces. This leads to precise fit and high clamping forces.

- Locking rings with thread Threaded locking rings can also be used in a temperature range from -40 to +175 °C. Threaded locking rings can be used on threaded rods or shafts with a thread tolerance of 6g. The thread surround the shaft with an equal distribution of clamping forces.

Shaft collars

Three of the products in the category are shaft collars. Two of the shaft collars are standardised according to DIN standard 705. They are made of steel or stainless steel. Respective shaft collars are briefly described below

- Shaft collars acc. to DIN 705 made of steel

- These are available in two forms:

- Form A – with grub screw acc. to DIN 553, can be installed with a slotted screwdriver.

- Form B –with grub screw acc. to DIN 914, can be tightened with a hexagon socket wrench.

- For surface of the base body it is possible to choose between bright or electro zinc-plated, blue passivated

- These are available in two forms:

- Shaft collar acc. to DIN 705 made of stainless steel

- Is made of stainless steel 1.4305

- Shaft collar is available in bright.

- You can also choose between two forms, DIN 553 with slit and DIN 914 with hexagon socket.

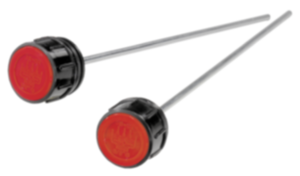

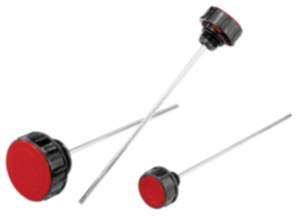

- Shaft collars with wing grip made of stainless steel

- Shaft collars are based on DIN standard 705.

- It features a adjustable stop

- Shaft collars are made of bright steel, wing grips are made of black-grey thermoplastic. The stud of the handles is made of steel grade 5.8 and is blue passivated.

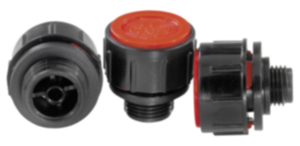

Clamping hubs

Clamping hubs by KIPP are made of high-carbon steel 1.1206.

For more information about the properties of high-carbon steel 1.1206 see our material overview.

clamp hubs are available with black oxide finish and can be quickly and easily fitted to shafts. After adjustment to the correct actuating position, clamp hubs are clamped onto the shaft. Bei use of fastening threads grip rods can be screwed to the clamp hub. To ensure reliable torque transmission, the tolerance of the shaft should not exceed h11!

Clamp hubs are available with an inside diameter of 10 mm, 12 mm, 14 mm or 16 mm and an outside diameter of 24 mm, 28 mm or 32 mm.

Selection criteria and installation of operating parts

The correct selection of shaft collars, locking rings or clamp hubs are crucial to ensure optimum performance and reliability in mechanical systems. Various factors must be taken into account when selecting these fastening elements. To ensure that operating parts meet specific requirements of your application, you should pay attention to the following criteria:

Load requirements

A key aspect in the selection of shaft collars, locking rings and clamp hubs is to take into consideration the load requirements of the application. This includes static as well as dynamic loads impacting the component. It is important to ensure that the selected fastening elements have the required load-bearing capacity and strength to support the load.

Diameter and size

Diameter and size of operating elements have to match the corresponding dimensions of the shaft and the component to be fastened. It is important that the fastening elements perfectly fit the shaft to ensure safe and stable connection.

Choice of materials

Choosing the appropriate material depends on ambient conditions and specific requirements of the application. It is important to choose materials that provide sufficient strength, corrosion resistance and resistance to other environmental impacts.

Compatibility and adaptability

Fastening elements should be compatible with other components and systems they interact with. It is important to ensure that they can be seamlessly integrated into the system as a whole and do not cause any conflicts with other components.

Taking these aspects into account, you are able to select the right shaft collars or locking rings as well as the right clamp hubs for your applications. Improve performance, reliability and efficiency of your mechanical systems today.

Do you have questions about products or are you not sure which operating part is right for your application? Then contact us. We are happy to help.

Care and precision are particularly important when installing operating parts. Therefore, check fit precision of the fastening element on the shaft before installation. Also make sure that the surface of the shaft is clean and free of dirt, rust or damage. If this is not the case, please clean it.

To position the operating part, place it on the shaft in the required position. Make sure that it is evenly aligned, flush and not tilted or crooked.

When fitting a shaft collar, you should check that the slits in the adjusting ring match the screw holes or other fixing points on the component.

Tighten the grub screw of the operating part evenly to exert even pressure on the shaft. Make sure to keep to the torque as recommended by manufacturer's instructions to avoid excessive stretching or damage to the material.

After installation, check that the operating part is securely fastened and correctly positioned on the shaft. Make sure it is tight and that there is no movement or looseness.

General tips for fitting locking rings, shaft collars or clamp hubs are obvious. Still, here is a little reminder.

- Use the right tools and keep to recommended torques to avoid damaging or deforming the fastening elements.

- Carry out a final check to make sure that all fastening elements are properly tightened and the component is securely fastened.

By following these instructions and tips, you can ensure trouble-free installation of locking rings, shaft collars and clamp hubs.

KIPP as a reliable partner for shaft collars, locking rings and clamp hubs

KIPP is a respected manufacturer of high-quality fastening elements. Many years of experience help us to gain a deep understanding for your requirements and needs.

A decisive factor for KIPP's success is its dedication to high quality standards. Fastening elements by KIPP are manufactured according to strict quality control procedures to ensure that the meet the challenging requirements of different applications. These quality controls cover the entire production process, from the selection of materials to the final inspection of the finished products.

We offer our customers a wide range of products covering different types of fastening element for a multitude of applications.

Also benefit from our many years of experience! You still have questions? Please contact us! We are always happy to help!