Drill bushes by KIPP

Drill bushes are indispensable components in manufacturing and metalworking technology. They are crucial, particularly when it comes to precision. The operating elements are used to precisely guide drills, reamers or other cylindrical tools during the machining process.

This ensures that holes are drilled with minimum deviation from nominal dimensions. This is particularly important in modern manufacturing processes. The importance of drill bushes covers numerous areas of application, ranging from CNC machines to tool and fixture construction. Operating parts notably play an important role in series production, as they ensure consistently high quality and accuracy of fit of components.

Depending on the application, different types of bushes are used to fulfil the requirements in regard to flexibility and durability. The use of drill bushes ensures consistently high dimensional accuracy, often in the micrometre range.

Drill bushes by KIPP

What is a drill bush?

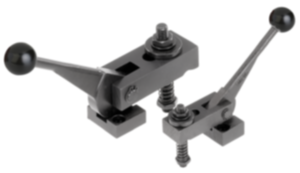

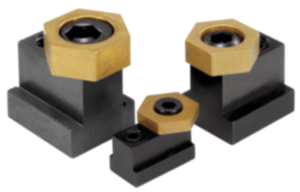

Drill bushes acc. to DIN 172 - Flanged drill bushes

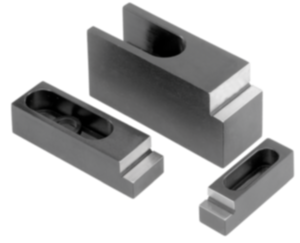

Cylindrical drill bushes acc. to DIN 179

What are the advantages of drill bushes?

Selecting the right drill bush

Why drill bushes by KIPP?

What is a drill bush?

Drill bushes are cylindrical operating parts made of hardened steel. They are the guide element for drills or other tools to ensure precise drilling. Additionally, bushes allow for a standardised drilling process and facilitate positioning applications in mechanical engineering and plant construction. That is why they are also known as positioning bushes.

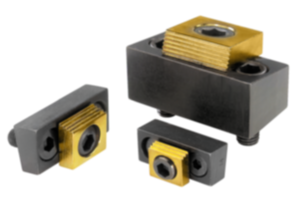

The use of bushes not only simplifies and optimises the drilling process. In combination with indexing plungers or positioning pins operating elements support fastening processes and facilitate alignment of mounts.

KIPP offers two types of drill bushes or positioning bushes according to DIN standards DIN 179 and DIN 172. These are available in different lengths and shapes.

Drill bushes acc. to DIN 172 - Flanged drill bushes

Drill bushes by KIPP are manufactured according to DIN 172. They are made of special case-hardened steel, are hardened and ground.

DIN 172 specifies dimensions and tolerances for flanged drill bushes. This includes:

- Diameter of the drill bush (inner and outer diameter)

- Height of the flange and total length

- Specified fitting tolerances for optimum guidance of the tool

Flanged drill bushes acc. to DIN 172 have a cylindrical shape with a flange attached to the side. This serves as a stop and ensures axial fastening and precise positioning. The flange also prevents the drill bush from slipping into the fixture during drilling.

The KIPP range allows you to choose between two forms of bushes:

- Form A: Rounded bore at one end (at the flange side)

- Form B: Rounded bore at both ends

In fixture construction, operating parts are used in drilling jigs and clamping devices. In the manufacturing process, bushes are particularly suitable for precision work in series production.

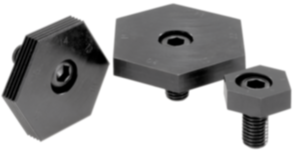

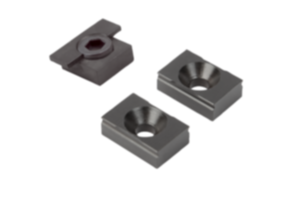

Cylindrical drill bushes acc. to DIN 179

Cylindrical drill bushes according to DIN 179 are standard components in tool and fixture construction. They are made from special case-hardened steel and hardened. They are ground to tolerance on both the inside and outside.

The cylindrically shaped drill bush can be precisely pressed into the mount and easily be use with plug-in drill bushes according to DIN 173.

KIPP provides two types of cylindrical bushes:

- Form A: Rounded bore at one end

- Form B: Rounded bore at both ends

In machine tools, cylindrical drill bush according to DIN 179 is used as a component of fixtures or tool holders. When building a drilling jig, cylindrical bushes are used for precise guidance of drills or reamers. In series production, it ensures repeatable and exact bores in components.

What are the advantages of drill bushes?

Drill bushes offer numerous advantages that make them essential components in production and fixture construction.

The greatest advantage is found in their ability to precisely guide drilling tools. This results in consistently high dimensional accuracy of drill holes. This is particularly important in series production, where repeatable results are required. Bushes also reduce the load on drilling tools, as they minimise vibrations and ensure axis alignment.

An additional advantage is that drilling points do not have to be measured or marked repeatedly. These bushes allow for precise guidance of the tool and ensure accurate drill holes with minimal deviations from nominal dimension. This property makes them perfect as positioning and guide bushes and considerably simplifies standardised drilling processes. They also contribute to a consistently good result, as they ensure a fixed penetration angle of the drilling tool.

Another advantage is found in the material quality of both products. The use of hardened and ground special case hardened steel ensures high wear resistance and durability, even under heavy use. The material makes the bushes particularly heat- and corrosion-resistant. This also renders them suitable for demanding operating conditions in industrial production.

Flexibility of drill bushes marks another advantage. Flanged drill bushes are standardised, according to DIN 172 for example, which makes them easy to replace without the need for major adjustments to the fixture. This in turn reduces downtimes and reduces maintenance costs in the long term.

Thanks to standardised dimensions, as DIN 179 for cylindrical drill bushes, the bushes are also compatible with a wide range of machines and devices.

Easy handling and installation of the parts is yet another major advantage. They can be securely fastened using press fits, screw connections or locking elements. They also protect the device from material wear, which extends its service life. Finally, drill bushes offer a high level of cost-effectiveness, as their sturdiness and precision increase production quality and reduce error-related costs.

Overall, bushes offer a combination of precision, time saving and easier handling. This makes the operating units essential tools in modern metalworking.

Selecting the right drill bush

Selecting the right drill bush is a crucial step to ensure precision and efficiency. Several criteria should be carefully considered when deciding on a suitable drill bush.

Initially, the area of application is of great importance. Different applications, such as manual drilling, CNC machines or specialised drilling jigs, require specific bushings.

The material of the workpiece also plays a major part. Harder materials such as steel or titanium, for example, require wear-resistant bushes made of hardened steel.

Another important point is the choice of drill bush type. Cylindrical bushes according to DIN 179 are ideal for compact devices. Flanged drill bushes according to DIN 172, on the other hand, provide additional stability and fixed positioning. This is particularly advantageous in precise guidance applications.

Dimensioning of drill bushes is also decisive for functionality and precision of the bore. The inner diameter should be precisely aligned to the diameter of the tool. This prevents play and vibrations that could impair dimensional accuracy.

Additionally, length and outer diameter of bushes have to meet the requirements of the mounting bore. This ensures stable fastening. Incorrect dimensioning may not only reduce the accuracy of the bore, but also shorten the service life of drill bushes and tools.

Quality features also play a key role in the selection process. High-quality drill bushes are characterised by close manufacturing tolerances. Certifications such as DIN standards are a key indicator of compliance with high quality standards.

In conclusion, it can be said that choosing the right drill bush requires careful consideration of different criteria. By taking these factors into account, it can be ensured that drill bushes:

- perfectly fits the area of application

- delivers precise results

- has a long service life

Why drill bushes by KIPP?

For more than 100 years, KIPP has stood for reliability and quality. Due to specialisation in the are of standard elements, bushes by KIPP not only ensure a high degree of fitting accuracy, but also a long service life.

A large number of drilling and positioning bushes are available from stock and can be delivered quickly.

We will be happy to design your custom solution upon request.

Drill bushes (positioning bushes) from KIPP

Drill bushes, also used as positioning bushes, are practical standard elements that guide a drill in a drilling jig. The use of drill bushes simplifies and optimises the drilling process at the workplace. Their versatility give them a wide range of possible applications, they are also often used as positioning bushes. Drill/positioning bushes from KIPP enable a standardised drilling process and facilitate positioning applications in machine and plant construction. In combination with KIPP indexing plungers or locating pins, they support fixation processes and simplify the alignment of assembly pieces. This is why the bushes are also used in other industrial branches, such as the automotive industry.

At KIPP you will find DIN 179 and DIN 172 drill and positioning bushes in various lengths and styles. Both flanged drill bushes and cylindrical drill bushes are available in the online shop.

DIN 172 drill bushes - flanged drill bushes

As per DIN 172, flanged drill bushes from KIPP are manufactured from special case-hardening steel, then hardened and ground. They are characterised by their protruding collar. This prevents the bush from being pushed through the adapter during use. There are two different types of flanged drill bushes: - Form A: bore rounded at one end ( flange side) - Form B: bore rounded at both ends

DIN 179 drill bushes - Cylindrical drill bushes

DIN 179 drill bushes are cylindrical drill bushes. They are also manufactured from special case-hardening steel and then hardened and ground. The cylindrical form of the bush enables it to be pressed flush into the adapter. Cylindrical drill bushes are available in two styles: - Form A: bore rounded at one end - Form B: bore rounded at both ends

KIPP drill and positioning bushes - Your advantages at a glance:

- Drilling points do not have to be repeatedly measured and marked

- Drill runs straight and true, even with cylindrical workpieces

- Consistently good results due to a fixed penetration angle

- Easier and quicker positioning of workpieces on mounting plates

- Adaptation of drill holes for the precise location of indexing plungers

Why drill bushes from KIPP?

For more than 100 years, KIPP has stood for reliability and quality. KIPP's specialisation in standard elements guarantees not only a high precision fit, but also a long service life. A large number of drill and positioning bushes are available from stock and can be delivered quickly. On request, we will be happy to develop a customised solution for you.