Material

Housing aluminium.

Piston steel.

Piston steel.

Version

Piston hardened.

Show more

Show less

Description

Product description

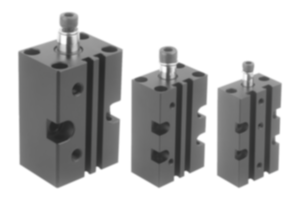

Rotary lever clamps are highly suited for use in cramped conditions. Due to the compactness of the rotary lever clamps, they can be used in a variety of ways in clamping fixtures with little use of space and thus often enable flexible solutions.

Material

Housing aluminium.

Piston steel.

Piston steel.

Version

Piston hardened.

Note

By the rotary lever clamps, the clamping lever is connected to the piston rod. The air supply for the rotary lever clamps is via drilled channels.

The clamping lever moves towards the workpiece with a linear stroke and clamps it. When releasing, the clamping lever retracts so far that the workpiece can be removed vertically. The single stroke of a rotary lever clamp depends on the clamping lever selection.

The clamping elements must be checked regularly for dirt and cleaned if necessary.

When selecting the installation position, it must be ensured that no swarf nests can form in the swivel area of the lever of the rotary lever clamp.

The flange surface of the rotary lever clamp should be adapted to the height of the workpiece during installation and a horizontal positioning of the clamping point should be available.

By positioning the rotary lever clamp correctly, workpiece tolerances can be optimally compensated for despite the short clamping lever.

High forces can be generated with the rotary lever clamps. It must be ensured that the workpieces and clamping fixtures are designed for these loads.

Rotary lever clamps can be fitted with individual tension levers. The clamping force of a rotary lever clamp is dependent on the lever length.

The tension lever for the rotary lever clamp is not supplied.

Follow safety instructions.

The clamping lever moves towards the workpiece with a linear stroke and clamps it. When releasing, the clamping lever retracts so far that the workpiece can be removed vertically. The single stroke of a rotary lever clamp depends on the clamping lever selection.

The clamping elements must be checked regularly for dirt and cleaned if necessary.

When selecting the installation position, it must be ensured that no swarf nests can form in the swivel area of the lever of the rotary lever clamp.

The flange surface of the rotary lever clamp should be adapted to the height of the workpiece during installation and a horizontal positioning of the clamping point should be available.

By positioning the rotary lever clamp correctly, workpiece tolerances can be optimally compensated for despite the short clamping lever.

High forces can be generated with the rotary lever clamps. It must be ensured that the workpieces and clamping fixtures are designed for these loads.

Rotary lever clamps can be fitted with individual tension levers. The clamping force of a rotary lever clamp is dependent on the lever length.

The tension lever for the rotary lever clamp is not supplied.

Follow safety instructions.

Method of operation

Drilled channels.

Technical Data

Max. operating pressure: 6 bar.

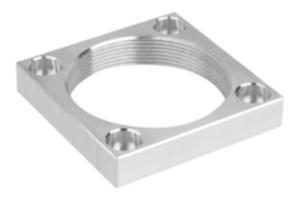

Assembly

See mounting contour.

Advantages

- No lateral forces during clamping.

- Low mounting dimensions.

- Wide selection of levers.

- Collision-free accessibility to the workpiece.

- Lineless pressure supply.

- Low mounting dimensions.

- Wide selection of levers.

- Collision-free accessibility to the workpiece.

- Lineless pressure supply.

Scope of delivery

Supplied with 4 DIN EN ISO 4762 cap screws, grade 8.8.

On request

Larger piston diameters, longer strokes and with position control.

Drawing reference

1) Tension lever length (see K1857)

2) Travel (see K1857)

3) See accessories

4) Mounting contour

5) Rounded edges

6) Loosen

7) Clamping

2) Travel (see K1857)

3) See accessories

4) Mounting contour

5) Rounded edges

6) Loosen

7) Clamping

Accessory

Tension levers for rotary lever clamps K1857.

Important note on downloading CAD models

You must log in before you can download our CAD models. If you have not yet created an account, please register under "My account" (right-hand side of the screen) and follow the instructions.