Křížové úchyty / hvězdicové úchyty / upínací úchyty

Clamping grips, star grips and palm grips are primarily used as retaining and fastening elements for manual tasks. An ergonomic design is among the key features of these products. They come in a range of different materials, sizes and shapes, allowing them to be used in applications such as machine construction and the chemical industry.

Palm grips and star grips by KIPP

Grip types and shapes play a decisive role in the ergonomics and functionality of tools and machines. Two frequently used grip shapes are palm grips and the star grips. These grips where developed to make handling of tools easier, increase efficiency and ensure safety.

Palm grips are characterised by their cross-shape, in which two parts of a grip are arranged perpendicularly to each other. It offers an ergonomic shape that allows comfortable handling and good control. The cross-shaped arrangement of the grip allows a high torque to be applied, which is particularly important for applications that require a lot of force.

The star grip, on the other hand, features a star-shaped grip part. This shape offers optimum grip and leverage, which makes turning and handling easier. Star grips are often used for handwheels, valves and machines where precise and powerful handling is required. The shape of the star grip allows for longer turning times without significant hand fatigue, as the force is well distributed.

Operating parts such as the palm grips and star grips are vitally important in industry and other sectors. Their specific shape is adapted to different requirements and applications. However, both grip shapes contribute to efficiency, safety and ergonomics in the operation of machines and tools.

The right choice grip shape depends on specific use and user requirements.

What are palm grips?

What are star grips?

Fastening elements by KIPP

Palm grips and star grips – Your advantages at KIPP

What are palm grips?

A palm grip is an operating part that features grips arranged in a cross-shaped which extend around a central point. This arrangement allows the user to achieve a firm grip and high power transmission. Palm grips are therefore particularly suitable for applications that require precise turning and a good grip.

Palm grips have two main functions:

- Torque transmission: Palm grips are used to transfer high torque to screws, bolts or other mechanical parts. Making them perfect for tightening and loosening fastening elements.

- Positioning and fastening: They are used to fasten components in certain positions or to precisely adjust them.

Advantages of the cross-shaped grip are ergonomics and high power transmission. The shape of the palm grip enables comfortable handling and reduces fatigue during prolonged use. In addition, the cross-shaped structure allows considerable force to be applied without the user having to exert excessive pressure.

Palm grips can be used in different industries and applications, from machine operation to fine adjustment.

KIPP offers a variety of palm grips that differ in terms of material, design and specific functions.

Palm grips made of stainless steel and plastic

Palm grips made of stainless steel are widely used in industry and are characterised by high strength and corrosion resistance. Stainless steel is a very sturdy material that can withstand high mechanical loads. This makes the stainless steel palm grips perfect for applications that require high durability.

Stainless steel is also impervious to rust and many chemicals, making it suitable for use in damp or corrosive environments. The hygienic properties are a further advantage of stainless steel, as it is easy to clean and disinfect. For this reason, stainless steel grips are often used in food processing and medical technology, where strict hygiene standards have to be complied with.

They are also used in the chemical industry as they are able to withstand aggressive chemicals.

Plastic palm grip provide a cost-effective and versatile solution for many industrial applications. Plastic is much lighter than metal, which makes handling easier and reduces the overall weight of machines and appliances. This can be particularly advantageous in production, where ergonomic factors and weight reduction are an issue.

Plastic grips are also generally cheaper to manufacture and purchase, which makes them an economical choice. Another advantage of plastic is its natural resistance to corrosion, as it does not rust and is impervious to many chemicals.

Plastic grips are ideal for general machine construction, the electronics industry and leisure equipment. In the electronics industry they are greatly appreciated because they are non-conductive and therefore do not cause any electrical interference.

Palm grips with thread

Palm grips with threaded inserts offer an outstanding combination of ergonomic handling and increased mechanical stability. The integration of metal threaded inserts in the grips body ensures durable and precise power transmission, which is crucial for many industrial applications. Whether in machine construction, toolmaking, medical technology or automotive and aviation industries - these special palm grips are versatile and offer reliable performance under demanding conditions.

The KIPP range includes palm grips with different types of thread. such as internal or external thread, hexagon socket or hole. Use the filter function to find the right type of grip for your application.

Palm grips according to DIN 6335

Several palm grips are standardised according to DIN 6335. DIN 6335 defines palm grips, which are used as operating elements for the transmission of torques and the precise adjustment of machines and devices. The standard ensures that palm grips are standardised, which guarantees exchangeability and compatibility of components in the industry.

Properties of palm grips according to DIN 6335:

Materials: Palm grips according to DIN 6335 can be made of different materials such as plastic, steel, stainless steel or cast iron. The choice of material depends on the requirements in regards to strength, corrosion resistance and operating environment.

Shape: The typical shape of a palm grip in accordance with DIN 6335 consists of two intersecting grips that form a cross-shaped arrangement and allow for efficient force transmission.

Size: The standard defines different sizes and dimensions of the palm grip to allow widespread us in different machines and devices.

What are star grips?

A star grip it an operating element, that typically consists of a central body from which several radial arms extend, forming a star-shaped arrangement. This specific shape enables easy and comfortable handling as it offers the user a variety of grip options. Star grips are available in different materials and sizes and are used in numerous industrial and craft applications.

Star grips have three main functions:

- Torque transmission: Star grips allow for efficient transmission of torque, which is particularly important for safe operation, tightening or loosening screws, valves and other mechanical components.

- Fine adjustment: They are often used to make precise adjustments to machines and devices. Multiple gripping surfaces facilitate exact positioning and fastening of components.

- Ergonomic operation: The star-shaped arrangement of the grips offers several ergonomic hand positions, making operation more comfortable and less tiring.

Advantages of star grips:

- High grip due to star-shaped arms

- Versatility, as grips are available in a wide range of sizes and materials

- Ergonomics, due to the shape of the grip

- Sturdy and durable, as grips are made of resistant materials such as stainless steel, aluminium or high-quality plastic

Star grips according to DIN 6336

Star grips according to DIN 6336 are standardised operating elements. They are star shaped and are often used in industrial applications. The standard 6336 ensures that the star grips meet certain requirements in terms of measurements, material and load rating in order to guarantee uniform quality and exchangeability.

These standard parts consist of a central body from which several star-shaped grips extend. The star-shaped arrangement allows comfortable handling and effective power transmission. DIN 6336 specifies exact dimensions and tolerances to ensure that grips can be used universally in a wide range of applications.

Triangular, four lobe and five lobe grip

Besides grips manufactured according to DIN standard, there are triangular, four lobe and five lobe grips.

The main difference between triangular, four lobe and five lobe grips lies in the number of arms. Each offers specific ergonomic and functional advantages:

Triangular grips: Compact and space-saving, ideal for confined spaces as well as applications that require a sturdy and space-saving solution.

Four lobe grips: Symmetrical and ergonomic, offering high stability and grip, suitable for applications that require safe and strong operation.

Five lobe grip: Maximum stability and ergonomic versatility, perfect for demanding applications that require high forces and flexible handling.

The choice between these grips depends on the specific requirements of the application in question, with all types allowing comfortable and efficient handling due to their star-shaped arrangement.

Fastening elements by KIPP

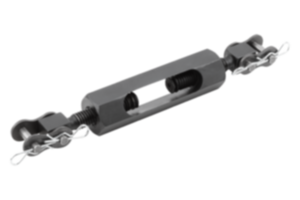

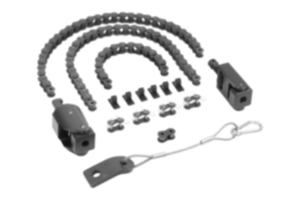

Beside star and palm grips the KIPP range also includes a safety band as an accessory and clamping grips.

Clamping grips differ to those presented above. They typically consist of a grip body that is ergonomically shaped and a clamping mechanism activated by turning or swivelling the handle. A distinction is made between high clamping grips and ergonomic clamping grips. Due to the high design of the clamping grip, higher clamping forces can be achieved comfortably by hand.

Palm grips and star grips – Your advantages at KIPP

KIPP is your reliable partner for high-quality operating elements, clamping technology and standardised parts. With decades of experience in production and development, we focus on quality, innovation and customer satisfaction. Our products, including star grips and palm grips, are tailored to the needs of the industry and are characterised by durability, ergonomics and precision.

By strict compliance to standards such as DIN 6335 or DIN 6336, we guarantee that our products meet the highest quality standards and offer reliable performance. KIPP provides an extensive range of operating elements that make your work easier, your machines and devices safe as well as precise to operate.